Review Article

Lean in Higher Educational Institutes: A Literature Review

- Abstract

- Full text

- Metrics

The application of Lean practices in higher educational institutes has gained tremendous attention in recent years as the sector strives to improve operational efficiency, enhance student outcomes, and efficiently manage resources. A comprehensive literature review is presented in this paper on the application of Lean methodologies in higher educational institutes. This paper seeks to answer the following research questions: 1) How is Lean methodology adopted by researchers in higher educational institutes? 2) Which Lean tools and methods are most suitable in higher educational institutes? 3) What are the barriers and challenges associated with implementing Lean in higher educational Institutes? 4) What is the future of Lean implementation in higher educational institutes? This literature review comprises a wide range of journal articles published in the last five years, from 2019 to 2023, retrieved from various academic databases, including Emerald Insight, Science Direct, Taylor and Francis, Web of Science, and Wiley Online. PRISMA protocol is used to collect and arrange the journal articles (36% analytical and 64% applied Lean) under several themes: (1) curriculum review and teaching methodology; (2) administration; (3) student satisfaction; (4) lean waste identification and elimination; and (5) barriers and challenges. The paper concludes that the Lean philosophy, which was originally formulated for the manufacturing sector, has been successfully adapted and applied to educational institutes. The application of Lean in higher educational institutes resulted in streamlined processes, waste reduction, and increased staff and student satisfaction levels. However, it also highlights the barriers and challenges such as cultural barriers, resistance to change, lack of knowledge among staff and students, and lack of leadership commitment. Overall, the review paper adds up to the existing body of knowledge by integrating and summarizing the key findings and trends in the application of Lean methodologies in higher education.

Lean in Higher Educational Institutes: A Literature Review

Shazray Khan*, Aurora Dimache, David Gorman, Carine Gachon

Department of Mechanical and Industrial Engineering, Atlantic Technological University Galway, Ireland

ABSTRACT

The application of Lean practices in higher educational institutes has gained tremendous attention in recent years as the sector strives to improve operational efficiency, enhance student outcomes, and efficiently manage resources. A comprehensive literature review on the application of Lean methodologies in higher educational institutes is presented in this paper. This paper seeks to answer the following research questions: 1) How is Lean methodology adopted by researchers in higher educational institutes? 2) Which Lean tools and methods are most suitable in higher educational institutes? 3) What are the barriers and challenges associated with implementing Lean in higher educational Institutes? 4) What is the future of Lean implementation in higher educational institutes? This literature review comprises a wide range of journal articles published in the last five years, from 2019 to 2023, retrieved from various academic databases, including Emerald Insight, Science Direct, Taylor and Francis, Web of Science, and Wiley Online. PRISMA protocol is used to collect and arrange the journal articles (36% analytical and 64% applied Lean) under several themes: (1) curriculum review and teaching methodology; (2) administration; (3) student satisfaction; (4) lean waste identification and elimination; and (5) barriers and challenges. The paper concludes that the Lean philosophy, which was originally formulated for the manufacturing sector, has been successfully adapted and applied to educational institutes. The application of Lean in higher educational institutes resulted in streamlined processes, waste reduction, and increased staff and student satisfaction levels. However, it also highlights the barriers and challenges such as cultural barriers, resistance to change, lack of knowledge among staff and students, and lack of leadership commitment. Overall, the review paper adds up to the existing body of knowledge by integrating and summarizing the key findings and trends in the application of Lean methodologies in higher education.

Keywords: Lean Methodology, Higher Educational Institutes, Review

Introduction

Drawing inspiration from the Toyota Production System, Lean Management aims to eradicate inefficiencies in the processes and enhance them to eliminate wasteful activities (Persoon et al., 2006; Shokri, 2017). This approach is adaptable to diverse settings and can be implemented using a variety of tools (Koskela et al., 2019). Often referred to as Lean thinking, Lean management requires clear objectives to augment the value of the product. Notable benefits observed in the realm of education encompass improvements in grade assessment systems (Nallusamy & Rao, 2018), reduced paper waste in photocopying and cafeteria operations (Sunder & Antony, 2018), and the identification of the primary customer and what value means for them (Petrusch et al., 2019).

The progress of nations in the 21st century, in terms of their economic, cultural, and social development, is intricately linked to the quality of education their educational institutions provide. Consequently, educational institutions are conducting research to identify their most significant stakeholders, identify areas requiring enhancement, and formulate strategies for implementing these improvements. These efforts aim to bring about constructive changes in both administrative and educational domains, ultimately increasing the value of their educational offerings (Emilian, 2005; Lemahieu, Nordstrum & Greco, 2017). Suárez-Barraza et al. (2012) note that discussions on the implementation of Lean principles in education commenced in 1993 during a forum dedicated to improving educational quality in Europe. Notably, the first documented application of Lean management in the context of Higher Education Institutions (HEIs) occurred two years later, with author Van Der (1995) exploring how Lean methods could enhance communication among HEI sectors. The study conducted by Klein et al. (2022) aimed to investigate the perception of Lean management methods inside higher education institutions (HEIs) and their impact on organizational performance. It identified Lean management practices that positively influenced the organizational performance of the HEI, including leadership support and employee involvement, focus on internal customers, long-term thinking, community services value, elimination of waste, and continuous improvement.

Davidson et al. (2020) highlighted the need for quality frameworks in higher educational institutes and emphasized continuous improvement using Lean Six Sigma. They presented a literature review on the use of quality frameworks in Higher educational institutes and identified tools and techniques that are missing in those frameworks. Francescatto et al. (2022) summarized the challenges and difficulties in implementing Lean Six Sigma tools and techniques in higher educational institutes, whereas Kakouris et al. (2022), in their systematic literature, identified some critical failure factors of Lean Six Sigma implementation in higher educational contexts. To the best of our knowledge, no work was published that identifies themes and areas of implementation of lean in a broader aspect in higher educational institutes. This literature review aims to seek the answers to the following research questions through a literature review of papers from the past five years (January 2019 to April 2023).

RQ1: Where has Lean methodology been applied by researchers in higher educational institutes?

RQ2: Which Lean tools and methods are most suitable in higher educational institutes?

RQ3: What are the barriers and challenges associated with implementing Lean in higher educational Institutes?

RQ4: What is the future of Lean implementation in higher educational institutes?

The upcoming sections of the papers are sectioned as Research Methodology – Section 2, Results and Discussions – Section 3, Conclusions, Limitations, and Future Work Suggestions – Section 4.

Research methodology

A systematic literature review is a rigorous and transparent methodology to identify, analyze and synthesize existing literature relevant to the specific research question(s). It aims to minimize bias and gives a reliable summary of the available evidence (Andrews, 2005; Dixon-Woods et al., 2006; Torgerson, 2006). The steps involved in the systematic literature review are as follows: 1) Formulating the research question, 2) Developing inclusion and exclusion criteria, 3) Search strategy, 4) Study selection, 5) Data extraction, 6) Quality assessment, 7) Data synthesis and 8) Reporting (Bettany-Saltikov, 2016). This research reviews literature extracted from some prominent databases including Emerald Insight, Science Direct, Taylor and Francis Online, Web of Science, and Wiley Online. The selected databases are very well-known scholarly platforms and provide access to a wide range of journals, articles, and other research materials. All these databases provide users with advanced search options including specific keywords, titles, authors, abstracts, publication years, etc, which make the extraction of relevant information effective. Moreover, the databases provide other features that include but are not limited to abstracts and metadata, citation information, and user customization. The mentioned databases were searched for the relevant papers published in the last five years. The research papers from academic journals written in English are selected for this research because English is a universally accepted language with a long history of publishing scientific research. Many established and prestigious journals are published in English, and researchers often reference and build upon existing literature in these journals.

The literature review was performed using Preferred Reporting Items for Systematic Reviews and Meta-Analysis Protocol (PRISMA). It covers the following four stages of performing a systematic literature review: 1) Identification, 2) Selection, 3) Eligibility, and 4) Inclusion (Page et al., 2021; Swartz, 2011).

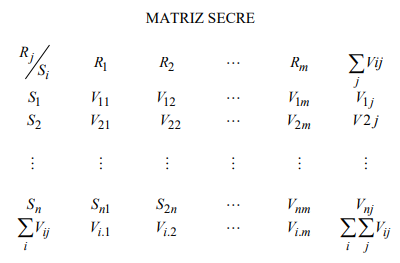

The combination of keywords such as “Lean”, “Lean Management”,” Lean Principles”, “Education”, “Educational Institutes”, and “Higher Education” along with the Boolean operator “AND” was used to search the databases. The Boolean operator “OR” was also used but it did not result in any significant results and some of the databases do not allow the Boolean operator “OR” in their search options. The results of the keywords are presented in Table 1.

Table 1. Results of search of keywords on databases

Keywords | Emerald Insight | Science Direct | Taylor & Francis Online | Web of Science | Wiley Online |

| Lean AND Education | 39 | 77 | 23 | 553 | 7 |

| Lean AND Educational Institutes | 15 | -- | 3 | 1 | -- |

| Lean Management AND Education | 19 | 19 | 3 | 42 | -- |

| Lean Management AND Educational Institutes | 15 | -- | 2 | -- | 2 |

| Lean AND Higher Education | 31 | 29 | 3 | 32 | -- |

Lean Management AND Higher Education | 3 | 6 | 1 | 20 | -- |

| Lean Principles AND Education | 8 | -- | -- | 6 | -- |

| Lean Principles AND Educational Institutes | -- | -- | -- | -- | -- |

| Lean Principles AND Higher Education | -- | -- | -- | 4 | -- |

Total | 130 | 131 | 35 | 658 | 9 |

| After Eliminating Duplicates | 65 | 81 | 23 | 553 | 7 |

| Relevant | 32 | 11 | 7 | 89 | 2 |

A total of 963 search results were generated by these keywords from all five databases. Zotero citation software was used to remove any duplicate results before the screening. It identified 234 duplicate results within the five databases. After removing the duplicate records, a total of 729 papers were moved to the next phase for screening the content. At the beginning of the screening phase, the titles and abstracts of all the papers were read, and 588 research papers were removed from the list. The remaining 141 research articles were sought for full-text retrieval, and only 137 full-text documents could be retrieved.

The next stage of PRISMA is eligibility. These 137 papers were analyzed, and it resulted in only 76 papers being aligned with the theme of our review. Hence, this literature review consists of the critical analysis of 76 research articles published between January 2019 and May 2023. All the steps of PRISMA are summarized in Figure 1.

A critical analysis of the included 76 papers was carried out, and the following sub-headings were discussed in the discussion section;

(1) Curriculum review and teaching methodology;

(2) Administration;

(3) Student satisfaction;

(4) Lean waste identification and elimination; and

(5) Barriers and challenges.

Figure 1. PRISMA (Identification of studies via Databases)

Results and discussions

The research papers were analysed and divided into two main themes i.e. Analytical research papers and applied research papers. It was found that 36% of the papers included in this review were analytical papers; the researchers have only proposed certain frameworks for implementing the lean in HEIs. The rest of the 64% of research papers were classified as applied papers in which the researchers have applied the lean in certain areas of HEIs and came up with some practical results of their studies.

Figure 2 shows an increasing trend in the number of publications by each year; in 2019, there were 15 studies; in 2020, there were 16 studies; in 2021, the number of published studies is higher compared to any other year i.e. 19. In 2022, there is a slight reduction in the number of publications, but it is close to the previous years. The graph shows only eight publications for 2023 because the papers published only till April are included in this study.

Figure 2. Publications by years

Figure 3 shows a graph that includes the number of publication by each country; the United States of America and Brazil is at the top of the list with 13 and 12 publications, respectively. The red bar at the right-most end shows the combined publications of all the European countries, which are summed up as 20 publications in the last five years.

Figure 3. Publications by Country

Table 2 shows the number of articles under each theme. The rest of the article discusses the main themes that emerged from the study.

Table 2: No. of articles under each theme

Themes emerged from the study | No. of Articles |

Curriculum Review and Teaching Methodologies | 32 |

Implementation of Lean in the Administrative Sector | 11 |

Implementation of Lean for Student Satisfaction | 06 |

Identification and Elimination of Lean Wastes | 08 |

Barriers and Challenges in Implementation | 09 |

The papers are further divided under themes, and the discussion on each theme is as follows:

Curriculum review and teaching methodologies

Out of the 76 papers included in this literature review, 32 articles analysed the use of Lean methodology in improving the curriculum for higher educational programs and enhancing teaching methods. Before 2016, most of the papers focused on implementing Lean tools and techniques in administrative offices of educational institutes such as libraries, concealer offices, IT offices, etc. The focus of the researchers shifted from the implementation of Lean in the administrative sector of educational institutes towards the implementation of Lean in curriculum review and teaching methodology after the year 2016. Adeinat et al. (2021) contributed to the literature by implementing Lean Six Sigma using the DMAIC methodology through the development and management of the assurance of the learning process, which is a systematic approach for revising the learning objectives and curriculum for a degree program. Their case study identified three critical aspects of Lean Six Sigma including clear identification of team members' responsibilities, fostering collaboration through a common language, and the identification of quantifiable priorities. The study provides recommendations for assessing, evaluating, and improving curriculum design and delivery in HEIs. de Waal and Maritz (2022), in their study, utilized a design thinking methodology and applied many methods, including empathy mapping, customer journey analysis, value proposition development, and semi-structured interviews. The objective of their research was to gain a comprehensive understanding of the challenges encountered by educators and students in the context of entrepreneurship education. They derived a conceptual solution having six phases: emergence, empathy, experimentation, and elaboration. In these phases, they identified the opportunity, gathered information about the context of the problem, generated ideas for potential solutions, and obtained constant feedback from educators and students.

A related study, grounded in lean principles, investigates the potential of collaborative learning in outcome-based engineering education (OBEE) (Bhat et al., 2020). The researchers used action research methodology and the PDCA approach to improve OBEE. The paper provides a step-by-step approach to the implementation of improvements in the OBEE system. The grading system is one of the important factors for HEIs, Oliver et al. (2019) presented a case study of implementing the Lean Six Sigma methodology in an instructional context, specifically in streamlining the grading process.

A novel approach Special Project Team, was described by Kaylan et al. (2022), and the focus of their idea was on identifying the prospects for enhancement of curriculum that are beyond a single course or rotation. The idea contributed to sustainable success and frequent reassessment, with a very high continuation rate for the projects initiated by the Special Project Team. The paper further demonstrated how the Lean startup method improved productivity and provided structure and accountability to an educational team led by the students.

The literature provides numerous records of the use of Lean for improving courses and reforming teaching methodologies. Deranek et al. (2021) supported the literature by comparing the efficacy of Lean methods versus traditional pedagogy in dental education. The effectiveness of a Lean A3 framework to locate waste, eliminate it, and reorganize the course has been evaluated by the authors. The outcome has reduced the process cycle times without compromising quality. Similar studies conducted by Singh (2021) and Monserrat et al. (2023) implemented Lean in the development of curriculum and industrial placement at an HEI and later used value stream mapping to represent and visualize the entire value chain of a computer science module. Hellberg and Fauskanger (2022) contributed to the design of quality improvement courses by highlighting the importance of integrating theory with real-life training and applying theory to practical problems. DMAIC is a widely used tool for the implementation of Lean Six Sigma in curriculum revision. Shanshan et al. (2021) used “DMAIC”, “text analysis”, “knowledge graph analysis”, and “topology graph analysis” to improve the curriculum system in HEI. They addressed the need to better meet the market, technical, and social requirements through an improved curriculum system and also highlighted the effectiveness of big data as a tool for decision-making in curriculum system improvement. Hasan et al. (2020) identified the reasons for the poor practical skills of engineering students in Bangladesh and suggested a learning process inspired by the Kaizen philosophy to address this issue. Sánchez et al. (2023) proposed a pedagogical game based on Continuous improvement cells and 5S and used planes made of paper to aid the demonstration of a production system for a construction company.

In their recent publication, Riemann and Metternich (2022) critically examined the potential benefits and constraints associated with the integration of Virtual Reality (VR) technology in the context of continuing education. Additionally, the authors outlined a set of feasible prerequisites that need to be fulfilled in order to effectively use VR in this domain. The authors introduced a methodology for the systematic and skill-focused development of virtual teaching-learning platforms. This approach facilitated the construction of virtual training programs that catered to the needs of learning factory operators and other training providers, with a specific focus on developing competencies and meeting user requirements. In a study conducted by Kregel (2019) an assessment was made to determine the potential impact of Kaizen on the enhancement of teaching quality within German higher education establishments. This research presents a novel methodology for expediting the assessment of teaching quality in real-time (referred to as Gemba) to enhance prompt responsiveness among educators.

In the years encompassing the pandemic (2019-2020), there was a notable increase in the utilization of online platforms for educational purposes. Fujs et al. (2022) introduced a methodology that facilitated the proficient utilization of remote conference tools by educators for a specific course. This approach aimed to enhance the efficacy of online education, particularly in the context of pandemics, benefiting both instructors and students. The strategy in this study draws upon the Kano model and centers on the assessment of remote conference tool functionalities from the viewpoints of both students and professors. Khandan and Shannon (2021) conducted a study to identify the primary sources of waste within three distinct teaching-learning environments, namely face-to-face, online, and hybrid. The findings of the study suggest that online instruction significantly impacts student engagement, as determined by the identification and weighting of non-value-added factors.

This section reveals a transformative shift in the application of Lean methodologies in higher education, transitioning from administrative offices to curriculum design and teaching methods after 2016. Studies demonstrate the efficacy of Lean tools, such as DMAIC and design thinking, in enhancing educational processes, with a notable focus on adaptability during the pandemic and innovative approaches like virtual reality and pedagogical games.

Teaching Lean in Curriculum

A subtheme has emerged in the context of curriculum revision and teaching methodology, encompassing articles that shed light on the inclusion of Lean methodologies in the curriculum. Lista et al. (2022) complement the literature by identifying teaching methods that support the development of both hard and soft skills. The authors emphasized the significance of integrating both conventional teaching approaches and active learning in Lean management training. They suggested incorporating active learning methods to aid in the understanding of intricate and abstract Lean management principles, specifically for the development of soft skills. Alves et al. (2021) conducted an exploratory investigation that examined the understanding and significance of incorporating Lean Education into academic courses. They analyzed the outcomes of workshops held at international conferences to encourage Lean Education as the ultimate content for new professionals. The authors believed that Lean Education equips professionals with the competencies needed to face the demands of the Fourth Industrial Revolution, such as whole system-thinking, sustainable consciousness, and ethical behavior. Tasdemir and Gazo (2020) developed a curriculum that integrated modern management techniques (Lean, Six Sigma, Supply Chain Management, and Life Cycle Changes) and the concepts of sustainability for the wooden products industry, focusing on project-based learning. They emphasized the need for redesigning and broadening the curriculum to become more real-life oriented and establish connections with industry and other institutions. Maware et al. (2023) analyzed the performance of 255 industrial participants (both in-person and online) on multiple Lean competencies and concluded that both the programs (in-person and online) resulted in an equally good performance on Lean systems and problem-solving. In one competency, Lean culture, the online participants outperformed the others, but overall, all the participants had positive feedback and experience. Similarly, Patching et al. (2023) discussed the collaborative design of a university education program that integrates “Building Information Modeling (BIM)”, “Integrated Project Delivery (IPD)”, and Lean methodologies. The importance of improving education in rapidly evolving technologies within integrated construction-related fields was underscored, with a focus on including essential interpersonal qualities such as open-mindedness, adaptability, teamwork, leadership, and communication. The program witnessed a total of 53 individuals successfully completing their studies, subsequently securing employment as BIM specialists within two months following their graduation.

In conclusion, all the studies presented above underscore the importance of integrating Lean principles into educational curricula, emphasizing a balanced approach that incorporates both traditional teaching methods and active learning for effective Lean management training. The studies also advocate for curriculum redesign, real-life orientation, and industry connections, reflecting a broader call for adaptability and relevance in educational programs.

Implementation of lean in the administrative sector

The implementation of lean in administrative offices of the HEIs was the major focus of the researchers during the early days of lean implementation in HEIs. Of all the articles included in this literature review, 11 articles applied lean principles in the administrative sector of HEIs. Daugherty and Lowry (2022) introduced three new tools named lean library, article galaxy scholar, and EBSCO custom linking in the libraries at the University of Alabama. The implementation enhanced the access and discovery of materials in the libraries and promoted interlibrary loan services. Oliveira et al. (2022) presented a case study that explored the adoption of a Kanban board in the bidding process and risk management process in the procurement department of a HEI. They concluded that the use of Kanban helped reduce threats and helped in effective problem-solving and optimization of the procurement process. Dempsey et al. (2020) identified the major wastes in the research grant application process in HEIs including editing and revising applications, communicating with collaborators, and waiting. The authors used the lean Six Sigma methodology to reduce these wastes from the application processes in the research office. A similar study used the structured lean Six Sigma methodology DMAIC to simplify the administrative processes and achieved improvement by reducing cycle times, cost, rework, and errors in the IT services, finance office, and registrar office of an HEI (O’Reilly, 2019). Another study that used the Lean Six Sigma methodology to improve the office move process was carried out by Wheeler-Webb and Furterer (2019). They emphasized the involvement of the stakeholders from the beginning till the end of the improvement process. They claimed that the other HEIs and industries with similar quoting, invoicing, and payment processes can benefit from their model. The concept of Lean Office was introduced by de Souza Lima et al. (2023), they followed lean evaluation and future improvement methods along with value stream mapping to evaluate the impacts of lean office implementation in HEI.

According to Benuyenah (2021), the human resource office plays a crucial role in the administrative setup of higher education institutions (HEIs). The author suggests that implementing a Lean strategy in academic recruiting might potentially mitigate the adverse impact of the discouraged job seekers paradox and alleviate the labor burden on human resources officers.

The paper suggests that applying lean principles, such as value stream, flow, and perfection, to higher education recruitment practices can lead to more efficient outcomes and satisfy the needs of employers. It highlights the potential benefits of using lean systems in educational settings beyond higher education, including further educational and non-tertiary institutions.

Cano et al. (2020) proposed a lean management framework for higher education that focused on creating value for stakeholders rather than cost-cutting and aimed to resolve problems associated with managerialism in the sector. The study identified four key categories for implementing Lean in HEIs: people and leadership aspects, technical and operational aspects of continuous improvement and process management, tools and measurement, and lean operations and program management. Petrusch et al. (2019) presented a descriptive and exploratory study that highlighted challenges in lean implementation in HEIs in Brazil. Jiménez et al. (2020) demonstrated how the 6S methodology can be applied to prevent the risk of SARS-CoV-2 spread in HEIs. Another novel study examined the effect of lean in reducing academic corruption by introducing the concept of positive organizational politics (Mahmoudi & Majd, 2021).

In the early stages of Lean adoption in Higher Education Institutes, the focus was on streamlining administrative processes, with diverse applications ranging from libraries to procurement. Studies highlighted the efficacy of Lean Six Sigma methodologies in reducing waste and improving efficiency, while challenges in implementation and innovative applications and emphasize the ongoing complexities in applying Lean principles to higher education.

Implementation of lean for student satisfaction

Students are one of the major stakeholders of any educational institution. Some studies show how they increased student satisfaction by adopting lean methodology in their HEIs. A case study was presented by Haerizadeh and Sunder (2019) that focused on baselining student satisfaction levels, reducing the waiting time, and increasing enrolments. They suggested that the use of the DMAIC methodology helped them to successfully achieve the level of student satisfaction that was desired. The researchers claim that there is a lack of understanding of what exactly students value in the services provided by HEIs. Petrusch and Vaccaro (2019) sought to fill this gap by presenting a conceptual framework that encompasses the value features associated with administrative and academic services in higher education institutions, as viewed by students. The eight value attributes encompassed in this study were reliability, empathy, access, responsiveness, self-service, communication, personalization, and imperceptibility. In a study conducted by Li et al. (2019), the utilization of Lean Six Sigma was showcased in the context of a university research office's pre-award service. Additionally, they discussed the obstacles and difficulties linked to the execution of Lean principles inside the specified service. The study conducted by Julião and Gaspar (2021) investigated the application of Lean thinking principles in the process of digitalizing services for students, to enhance their level of satisfaction. The researchers focused their efforts on developing online alternatives to traditional face-to-face methods for application submission, enrolment processes, and thesis submission.

Reduction in student dropout rate using lean was presented by Gupta et al. (2020). They conducted a qualitative study using the Lean Six Sigma methodology to understand the reasons behind the increasing student dropout rate. They proposed that the universities need to segment various kinds of student dropouts to better understand the problem.

The studies demonstrate the application of Lean methodologies in Higher Education Institutions (HEIs) has shown promise in enhancing student satisfaction. Studies addressing waiting times, service attributes valued by students, and the reduction of dropout rates underscore the potential of Lean principles in improving the overall student experience. These findings suggest that incorporating Lean strategies can contribute to more efficient and student-focused operations within educational institutions.

Identification and elimination of lean wastes

Eight research articles fall under this theme. The authors have identified the lean wastes from the administrative department as well as the teaching methods. Klein et al. (2021) employed an analytical hierarchy process approach to construct a multi-criteria matrix for the purpose of evaluating and assigning scores to a total of 24 different types of waste. According to the authors, the most relevant wastes to be treated at the HEI were loss of knowledge and over-processing. In a similar study, the authors used interpretative structural modeling to develop a structural model and identify the relation between the eighteen identified wastes (Hartanti et al., 2022). They also used failure mode and effect analysis to perform the risk assessment on these identified wastes.

Céspedes-Mota et al. (2021) applied lean manufacturing concepts to engineering education and used value stream mapping for the identification of wastes from educational institutes. In the same way, Potgieter et al. (2023) proposed a model incorporating the use of Kipling analysis and process flow mapping to understand the current state of the process. The paper focused only on part-time programs and their relation with the other entities in the university.

As far as the teaching process is concerned, Martínez Sanahuja (2020) and Mulyana et al. (2023) have proposed their respective frameworks aimed at identifying and eliminating activities within the teaching processes that do not contribute value. The latter also includes community services and supporting activities besides the teaching activities. They conducted questionnaire-based studies and evaluated the wasteful activities according to the responses of the participants. Mulyana et al. (2022) also used a waste assessment model to identify and assess the waste in teaching processes. Their study consisted of waste identification, assessment and root cause analysis steps. overproduction, non-utilized talent, and defects were the primary types of waste identified by their model.

A unique study proposed by Klein et al. (2023a) developed a scale for measuring the waste of knowledge in HEIs. The paper provides an application scale that can be applied to various other organizations for measuring waste of knowledge.

All these studies contribute insights into mitigating Lean wastes in administrative and teaching processes within Higher Education Institutions. Key findings emphasize addressing specific inefficiencies in administration (like loss of knowledge and over-processing) and teaching (such as overproduction, non-utilized talent, and defects).

Barriers and challenges to implementing lean

Implementing lean principles in an organization is often hailed as a promising pathway to increased efficiency, cost reduction, and enhanced overall performance. However, the journey towards achieving lean excellence is not without its share of hurdles and complexities. Simonyte et al. (2022) identified the complexity of the processes in educational institutes as one of the main barriers to lean implementation. They further commented that lack of strong leadership, commitment from top management, insufficient communication, lack of teamwork, resistance to change, lack of employee buy-in, and limited resources and funding are some of the barriers that hinder the smooth implementation of lean in HEIs. Allaoui and Benmoussa (2020) studied the attitude of employees in higher education towards change with lean at a public university in Morocco. They concluded that individual factors, such as curiosity and dissatisfaction with working conditions, are particularly important in motivating employees to embrace change with Lean. Similarly, Petrusch et al. (2019) highlighted the challenges of lean implementation and consolidation in HEIs, such as dealing with resistance from personnel and managers, communication problems, and the need to balance daily activities and improvement works.

Mathur et al. (2023) conducted a comprehensive examination of the reliability and effectiveness of utilizing seven quality tools within higher education institutions (HEIs). The main outcome of this study revealed that the adoption of quality tools in higher education institutions (HEIs) is not extensive. The study underscored the necessity of management support, comprehensive training, and the implementation of a continuous program to ensure the successful utilization of quality tools in HEIs. Researchers have employed a range of quality tools to facilitate the integration of Lean principles. However, the utilization of quality tools remains limited within the setting of Higher Education Institutions (HEIs). However, among all the quality tools, the Pareto chart and cause and effect diagram have been extensively employed in the setting of HEIs.

A novel study regarding the critical success factors of lean implementation in HEIs was conducted by Kokkinou and Van Kollenburg (2022). The study recommended a bottom-up implementation approach, focusing on improving university-wide supporting processes, promoting cross-departmental cooperation, and overcoming the silo mentality. They further commented that the key critical success factors are employee empowerment, sharing success stories, and training.

In summary, while implementing Lean principles in Higher Education Institutions (HEIs) offers potential for efficiency gains, numerous challenges exist. Barriers include the complexity of educational processes, leadership issues, resistance to change, communication problems, and limited resources. Recent studies highlight the importance of individual attitudes, employee empowerment, cross-departmental cooperation, and a bottom-up implementation approach in overcoming these hurdles. Additionally, ensuring widespread training and continuous programs is essential for the effective use of quality tools in HEIs.

Conclusions, Limitations and future Work Suggestions

In conclusion, the evolution of Lean methodologies in higher education is evident, emphasizing adaptability and innovation. The integration of Lean principles into curricula, addressing administrative inefficiencies, and enhancing student satisfaction underscore its potential. Challenges like resistance to change highlight the need for a holistic, adaptive approach for successful Lean implementation in Higher Education Institutions.

The limitations of this study are two-fold: The literature review covers only the papers that were published during the last five years (January 2019 to April 2023). A limited number of databases were searched because of resource and time constraints, and only journal-published papers written in English were selected to be added to the review. A number of gaps have been identified; they could be addressed in further studies. Some of them are discussed below.

As far as future research is concerned, none of the applied research papers discussed the long-term implementation of Lean culture and Lean practices in HEIs. It was observed that most of the implementation studies were carried out in STEM departments such as engineering, construction, medical science, and computer science etc. Lean is a general methodology and can be applied to any kind of educational setup and not only in science fields.

Very few comparison studies were found that compared the performance of different HEIs in different regions. In the future, researchers may conduct comparative studies among HEIs across various countries. Additionally, there is a need to analyze and compare challenges and barriers faced by public and private sector institutes. Most of the studies acknowledged the challenges and barriers that could arise during and after implantation of Lean in HEIs but none of the researchers performed applied research on overcoming these barriers and challenges. Moreover, a proper mapping of Lean wastes with the wastes in HEIs can be conducted.

Another aspect of future research could be optimizing and streamlining the activities of top-level management through Lean methodologies, which could result in overall benefits for the entire HEI. This could involve examining how Lean principles can enhance efficiency, communication, and collaboration among different departments within the institution, ultimately contributing to improved institutional performance and effectiveness.

References

Adeinat, I., Al Rahahleh, N., & Al Bassam, T. (2021). Lean Six Sigma and Assurance of Learning (AoL) in higher education: a case study. International Journal of Quality & Reliability Management, 39(2), 570-587. http://dx.doi.org/10.1108/IJQRM-01-2021-0017

Allaoui, A., & Benmoussa, R. (2020). Employees’ attitudes toward change with Lean Higher Education in Moroccan public universities. Journal of Organizational Change Management, 33(2), 253-288. http://doi.org/10.1108/JOCM-08-2018-0232

Alves, A. C., Leao, C. P., Uebe-Mansur, A. F., & Kury, M. I. R. (2021). The knowledge and importance of Lean Education based on academics’ perspectives: an exploratory study. Production Planning & Control, 32(6), 497-510. http://doi.org/10.1080/09537287.2020.1742371

Andrews, R. (2005). The place of systematic reviews in education research. British Journal of Educational Studies, 53(4), 399-416. https://doi.org/10.1111/j.1467-8527.2005.00303.x

Benuyenah, V. (2021). Can the concept of “lean management” be applied to academic recruitment?–a quasi-theoretical discourse. Rajagiri Management Journal, 15(2), 105-112. https://doi.org/10.1108/RAMJ-07-2020-0039

Bettany-Saltikov, J. (2016). EBOOK: How to do a Systematic Literature Review in Nursing: A step-by-step guide.

Bhat, S., Bhat, S., Raju, R., D’Souza, R., & Gopalakrishna, B. K. (2020). Collaborative learning for outcome-based engineering education: A lean thinking approach. Procedia Computer Science, 172(2), 927-936. http://doi.org/10.1016/j.procs.2020.05.134

Cano, M., Murray, R., & Kourouklis, A. (2022). Can lean management change the managerial culture in higher education? Studies in Higher Education, 47(4), 915-927. https://doi.org/10.1080/03075079.2020.1817892

Céspedes-Mota, A., Shenoy, D., & Cárdenas-Barrón, L. E. (2021). Application of lean manufacturing concepts to evolving a policy for engineering education. Education Sciences, 11(11), 755. https://doi.org/10.3390/educsci11110755

Daugherty, A. L., & Lowry, L. (2022). Three Product Implementations for Improving “Just-In-Time” Delivery of Library Resources. Technical Services Quarterly, 39(4), 351-368. https://doi.org/10.1080/07317131.2022.2125675

Davidson, J. M., Price, O. M., & Pepper, M. (2020). Lean Six Sigma and quality frameworks in higher education–a review of literature. International Journal of Lean Six Sigma, 11(6), 991-1004. http://doi.org/10.1108/IJLSS-03-2019-0028

de Souza Lima, E., de Oliveira, U. R., de Carvalho Costa, M., Fernandes, V. A., & Teodoro, P. (2023). Sustainability in Public Universities through lean evaluation and future improvement for administrative processes. Journal of Cleaner Production, 382(6), 135318. http://doi.org/10.1016/j.jclepro.2022.135318

de Waal, G. A., & Maritz, A. (2022). A disruptive model for delivering higher education programs within the context of entrepreneurship education. Education+ Training, 64(1), 126-140. http://doi.org/10.1108/ET-03-2021-0102

Dempsey, M., Brennan, A., & McAvoy, J. (2020). Barriers and waste in the research grant application process in higher education through a Lean Six Sigma lens. Management and Production Engineering Review, 11(3), 119-127. https://doi.org/10.24425/mper.2020.134938

Deranek, K., Kramer, S., & Siegel, S. (2021). Technology-dependent pedagogical process redesign: leveraging lean methods. International Journal of Quality & Reliability Management, 38(8), 1816-1832. http://dx.doi.org/10.1108/IJQRM-04-2020-0107

Dixon-Woods, M., Bonas, S., Booth, A., Jones, D. R., Miller, T., & Sutton, A. J. (2006). How can systematic reviews incorporate qualitative research? A critical perspective. Qualitative Research, 6(1), 27-44. https://doi.org/10.1177/1468794106058867

Emiliani, M. L. (2005). Using kaizen to improve graduate business school degree programs. Quality Assurance in Education, 13(1), 37-52. https://doi.org/10.1108/09684880510578641

Francescatto, M., Neuenfeldt Júnior, A., Kubota, F. I., Guimarães, G., & de Oliveira, B. (2023). Lean Six Sigma case studies literature overview: critical success factors and difficulties. International Journal of Productivity and Performance Management, 72(1), 1-23. http://doi.org/10.1108/IJPPM-12-2021-0681

Fujs, D., Vrhovec, S., Žvanut, B., & Vavpotič, D. (2022). Improving the efficiency of remote conference tool use for distance learning in higher education: A kano based approach. Computers & Education, 181, 104448. https://doi.org/10.1016/j.compedu.2022.104448

Gupta, S. K., Antony, J., Lacher, F., & Douglas, J. (2020). Lean Six Sigma for reducing student dropouts in higher education–an exploratory study. Total Quality Management & Business Excellence, 31(1-2), 178-193. http://doi.org/10.1080/14783363.2017.1422710

Haerizadeh, M., & Sunder M. V. (2019). Impacts of Lean Six Sigma on improving a higher education system: a case study. International Journal of Quality & Reliability Management, 36(6), 983-998. http://dx.doi.org/10.1108/IJQRM-07-2018-0198

Hartanti, L. P. S., Gunawan, I., Mulyana, I. J., & Herwinarso, H. (2022). Identification of waste based on lean principles as the way towards sustainability of a higher education institution: A case study from Indonesia. Sustainability, 14(7), 4348. http://dx.doi.org/10.3390/su14074348

Hasan, M. Z., Mallik, A., & Tsou, J. C. (2021). Learning method design for engineering students to be prepared for Industry 4.0: a Kaizen approach. Higher Education, Skills and Work-Based Learning, 11(1), 182-198. http://doi.org/10.1108/HESWBL-07-2019-0098

Hellberg, R., & Fauskanger, E. (2022). Learning of quality improvement theory–experiences with reflective learning from a student perspective. International Journal of Lean Six Sigma. https://doi.org/10.1108/IJLSS-04-2022-0090

Jiménez, M., Romero, L., Fernández, J., Espinosa, M. D. M., & Domínguez, M. (2020). Application of lean 6s methodology in an engineering education environment during the SARS-CoV-2 pandemic. International Journal of Environmental Research and Public Health, 17(24), 9407. https://doi.org/10.3390/ijerph17249407

Julião, J., & Gaspar, M. C. (2021). Lean thinking in service digital transformation. International Journal of Lean Six Sigma, 12(4), 784-799. http://dx.doi.org/10.1108/IJLSS-11-2020-0192

Kakouris, A., Sfakianaki, E., & Tsioufis, M. (2022). Lean thinking in lean times for education. Annals of Operations Research, 316(1), 657-697. https://doi.org/10.1007/s10479-021-04055-7

Kaylan, K. B., Russel, S. M., Justice, C. N., Sheena, M. K., Hirshfield, L. E., Heiman, H. L., & Curry, R. H. (2022). Applying the lean startup method to structure project-based, student-driven curricular enhancements. Teaching and Learning in Medicine, 34(4), 434-443. https://doi.org/10.1080/10401334.2021.1928501

Khandan, R., & Shannon, L. (2021). The effect of teaching–learning environments on student’s engagement with lean mindset. Education Sciences, 11(9), 466. http://doi.org/10.3390/educsci11090466

Klein, L. L., Tonetto, M. S., Avila, L. V., & Moreira, R. M. (2021). Management of lean waste in a public higher education institution. Journal of Cleaner Production, 286(1), 125386. http://dx.doi.org/10.1016/j.jclepro.2020.125386

Klein, L. L., Alves, A. C., Abreu, M. F., & Feltrin, T. S. (2022). Lean management and sustainable practices in Higher Education Institutions of Brazil and Portugal: A cross country perspective. Journal of Cleaner Production, 342, 130868. https://doi.org/10.1016/j.jclepro.2022.130868

Klein, L. L., Vieira, K. M., Alves, A. C., & Pissutti, M. (2023a). Demystifying the eighth lean waste: a knowledge waste scale. International Journal of Quality & Reliability Management, 40(2). http://dx.doi.org/10.1108/IJQRM-01-2022-0020

Klein, L. L., Vieira, K. M., Marçal, D. R., & Pereira, J. R. L. (2023b). Lean management practices perception and their influence on organizational performance in a public Higher Education Institution. The TQM Journal, 35(3), 673-697. http://dx.doi.org/10.1108/TQM-11-2021-0311

Kokkinou, A., & Van Kollenburg, T. (2022). Critical success factors of Lean in Higher Education: an international perspective. International Journal of Lean Six Sigma. http://doi.org/10.1108/IJLSS-04-2022-0076

Koskela, L., Ferrantelli, A., Niiranen, J., Pikas, E., & Dave, B. (2019). Epistemological Explanation of Lean Construction. Journal of Construction Engineering and Management, 145(2). https://doi.org/10.1061/(ASCE)CO.1943-7862.0001597

Kregel, I. (2019). Kaizen in university teaching: continuous course improvement. International Journal of Lean Six Sigma, 10(4), 975-991. http://dx.doi.org/10.1108/IJLSS-08-2018-0090

LeMahieu, P. G., Nordstrum, L. E., & Greco, P. (2017). Lean for education. Quality Assurance in Education, 25(1), 74-90. https://doi.org/10.1108/QAE-12-2016-0081

Li, N., Laux, C. M., & Antony, J. (2019). How to use lean Six Sigma methodology to improve service process in higher education: A case study. International Journal of Lean Six Sigma, 10(4), 883-908. https://doi.org/10.1108/IJLSS-11-2018-0133

Lista, A. P., Tortorella, G. L., Bouzon, M., Thürer, M., & Jurburg, D. (2022). Soft and hard skills development in lean management trainings. International Journal of Lean Six Sigma, 13(5), 1137-1158. http://dx.doi.org/10.1108/IJLSS-06-2021-0116

Swartz, M. K. (2011). The PRISMA statement: a guideline for systematic reviews and meta-analyses. J. Pediatr. Health Care, 25(1), 1-2. https://doi.org/10.1016/j.pedhc.2010.09.006

Mahmoudi, F., & Majd, R. B. (2021). The effect of lean culture on the reduction of academic corruption by the mediating role of positive organizational politics in higher education. International Journal of Educational Development, 80, 102319. https://doi.org/10.1016/j.ijedudev.2020.102319

Martínez Sanahuja, S. (2020). Towards lean teaching: non-value-added issues in education. Education sciences, 10(6), 160. http://dx.doi.org/10.3390/educsci10060160

Mathur, S., Antony, J., Olivia, M., Letícia, L. F., Shreeranga, B., Raja, J., & Ayon, C. (2023). An empirical study into the use of 7 quality control tools in higher education institutions (HEIs). The TQM Journal, 35(7), 1777-1798. https://doi.org/10.1108/TQM-07-2022-0222

Maware, C., Parsley, D. M., Huang, K., Swan, G. M., & Akafuah, N. (2023). Moving lab‐based in‐person training to online delivery: The case of a continuing engineering education program. Journal of Computer Assisted Learning, 39(1). http://doi.org/10.1111/jcal.12789

Monserrat, M., Mas, A., Calafat, A. L. M., & Clarke, P. (2023). Applying Lean to Improve Software Project Management Education. IEEE Transactions on Engineering Management. http://doi.org/10.1109/TEM.2023.3264981

Mulyana, I. J., Hartanti, L. P. S., Herdianto, V. A., Gunawan, I., & Herwinarso, H. (2022). Lean waste identification in higher education institution using waste assessment model. Management Systems in Production Engineering, 30, 200-206. https://doi.org/10.2478/mspe-2022-0025

Mulyana, I. J., Singgih, M. L., Partiwi, S. G., & Hermanto, Y. B. (2023). Identification and Prioritization of Lean Waste in Higher Education Institutions (HEI): A Proposed Framework. Education Sciences, 13(2), 137. http://dx.doi.org/10.3390/educsci13020137

Nallusamy, S., & Rao, G. V. P. (2018). Enhancement of pass percentage through lean six sigma approach in degree level technical educational institutions. International Journal of Engineering Research in Africa, 39, 191-201. http://doi.org/10.4028/www.scientific.net/JERA.39.191

O’Reilly, S. J., Healy, J., Murphy, T., & Ó’Dubhghaill, R. (2019). Lean Six Sigma in higher education institutes: an Irish case study. International Journal of Lean Six Sigma, 10(4), 948-974. http://doi.org/10.1108/IJLSS-08-2018-0088

Oliveira, T., Junior, J. V. M., Gurgel, A. M., & de Almeida Silva, V. (2022). Adoção do Kanban na Gestão dos Riscos no Processo de Compras em uma Instituição Pública de Ensino Superior. Contabilidade Gestão e Governança, 25(1), 60-79. https://doi.org/10.51341/1984-3925_2022v25n1a4

Oliver, J., Oliver, Z., & Chen, C. (2019). Applying lean six sigma to grading process improvement. International Journal of Lean Six Sigma, 10(4), 992-1017. https://doi.org/10.1108/IJLSS-03-2018-0029

Page, M. J., McKenzie, J. E., Bossuyt, P. M., Boutron, I., Hoffmann, T. C., Mulrow, C. D., Shamseer, L., Tetzlaff, J. M., & Moher, D. (2021). Updating guidance for reporting systematic reviews: development of the PRISMA 2020 statement. Journal of clinical epidemiology, 134, 103-112. https://doi.org/10.1016/j.jclinepi.2021.02.003

Patching, A., Skitmore, M., Rusch, R., & Lester, D. (2023). Case study of the collaborative design of an integrated BIM, IPD and Lean university education program. International Journal of Construction Management, 1-10. https://doi.org/10.1080/15623599.2023.2215107

Persoon, T. J., Zaleski, S., & Frerichs, J. (2016). Improving preanalytic processes using the principles of lean production (Toyota Production System). American Journal of Clinical Pathology, 125(1), 16-25. http://dx.doi.org/10.1309/865V7UMFPUKGCF8D

Petrusch, A., & Vaccaro, G. L. R. (2019). Attributes valued by students in higher education services: a lean perspective. International Journal of Lean Six Sigma, 10(4), 862-882. http://dx.doi.org/10.1108/IJLSS-07-2018-0062

Petrusch, A., Roehe Vaccaro, G. L., & Luchese, J. (2019). They teach, but do they apply? An exploratory survey about the use of Lean thinking in Brazilian higher education institutions. International Journal of Lean Six Sigma, 10(3), 743-766. http://doi.org/10.1108/IJLSS-07-2017-0089

Petrusch, A., Roehe, V. G. L., & Luchese, J. (2019). They teach, but do they apply? An exploratory survey about the use of Lean thinking in Brazilian higher education institutions, International Journal of Lean Six Sigma, 10(3), 743-766. https://doi.org/10.1108/IJLSS-07-2017-0089

Potgieter, N., Hattingh, T., & Fitchett, A. (2023). Lean Engineering in higher education: a case study at the University of the Witwatersrand, Johannesburg. Perspectives: Policy and Practice in Higher Education, 27(1), 26-36. https://doi.org/10.1080/13603108.2022.2099476

Riemann, T., & Metternich, J. (2022). Virtual reality supported trainings for lean education: conceptualization, design and evaluation of competency-oriented teaching-learning environments. International Journal of Lean Six Sigma. https://doi.org/10.1108/IJLSS-04-2022-0095

Sánchez, O., Revuelta, M. P., Gómez-Cabrera, A., & Salazar, L. A. (2023). Paper Planes for Teaching Construction Production Systems Based on Lean Tools: Continuous Improvement Cells and 5S. Buildings, 13(2), 558. https://doi.org/10.3390/buildings13020558

Shanshan, S., Wenfei, L., & Lijuan, L. (2022). Applying lean six sigma incorporated with big data analysis to curriculum system improvement in higher education institutions. International Journal of System Assurance Engineering and Management, 13(4), 1-16. http://dx.doi.org/10.1007/s13198-021-01316-3

Shokri, A. (2017). Quantitative analysis of Six Sigma, Lean and Lean Six Sigma research publications in last two decades. International Journal of Quality & Reliability Management, 34(5), 598-625. https://doi.org/10.1108/IJQRM-07-2015-0096

Simonyte, S., Adomaitiene, R., & Ruzele, D. (2022). Experience of lean application in higher education institutions. International Journal of Lean Six Sigma, 13(2), 408-427. http://dx.doi.org/10.1108/IJLSS-11-2020-0208

Singh, J. (2021). Applying lean methodology to curriculum revision and internship placement process–a case study. Journal of Research in Innovative Teaching & Learning, 14(2), 288-305. http://doi.org/10.1108/JRIT-05-2019-0055

Suárez-Barraza, M. F., Smith, T., & Dahlgaard-Park, S. M. (2012). Lean Service: A literature analysis and classification. Total Quality Management & Business Excellence, 23(3-4), 359-380. https://doi.org/10.1080/14783363.2011.637777

Sunder, M, V., & Antony, J. (2018). A conceptual Lean Six Sigma framework for quality excellence in higher education institutions. International Journal of Quality & Reliability Management, 35(4), 857-874. https://doi.org/10.1108/IJQRM-01-2017-0002

Tasdemir, C., & Gazo, R. (2020). Integrating sustainability into higher education curriculum through a transdisciplinary perspective. Journal of Cleaner Production, 265, 121759. https://doi.org/10.1016/j.jclepro.2020.121759

Torgerson, C. J. (2006). Publication bias: The achilles’ heel of systematic reviews? British Journal of Educational Studies, 54(1), 89-102. https://doi.org/10.1111/j.1467-8527.2006.00332.x

Van Der, W. T. (1995). Quality management in a teaching organization. Total Quality Management,6(5), 497-508. https://doi.org/10.1080/09544129550035161

Wheeler-Webb, J., & Furterer, S. L. (2019). A lean six sigma approach for improving university campus office moves. International Journal of Lean Six Sigma, 10(4), 928-947. http://dx.doi.org/10.1108/IJLSS-04-2018-0042

Download Count : 738

Visit Count : 1732

Keywords

Lean Methodology; Higher Educational Institutes; Review

How to cite this article:

Khan, S., Dimache, A., Gorman. D., & Gachon, C. (2024). Lean in Higher Educational Institutes: A Literature Review. Studies in Educational Management, 15, 1-19. https://doi.org/10.32038/sem.2024.15.01

Acknowledgments

Not applicable.

Funding

Not applicable.

Conflict of Interests

No, there are no conflicting interests.

Open Access

This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. You may view a copy of Creative Commons Attribution 4.0 International License here: http://creativecommons.org/licenses/by/4.0/